The notion of circular economy we will now discuss and which has officially entered into the French law on energy transition for green growth (in French, Loi relative à la Transition Énergétique pour la Croissance Verte) on August 18th, 2015, is closely linked to the notion of sustainable development.

Sustainable development and circular economy at the heart of the agglomeration market

We are evolving in a society in which questions of sustainable development, rejection of over-consumption, circular economy and research of alternative ways of consumption are more than ever hot topics. A lot of industrial companies are increasingly confronted to a new problem: the one to know how they can reuse their production by-products instead of processing them as a waste with a prohibitive external cost. Some of them found a solution: they recycle their fines and by-products into a secondary raw material reusable into their production line. This solution often calls on agglomeration, a process that involves briquetting or compaction techniques.

In order to better understand these issues that concern our market, let us first define the main two concepts of sustainable development and circular economy and then show in what the agglomeration market, and more precisely the activity of Euragglo, fall within these approaches.

Sustainable development: what is this?

According to the quote gave in 1987 by Mrs. Gro Harlem Brundtland (former Norwegian Prime Minister and President of the World Commission on Environment and Development of the United Nations) which is now known as its official definition, sustainable development is “a development that meets the needs of the present without compromising the ability of the future generations to meet their own needs. The two key concepts of sustainable development are : the concept of “needs” in particular the essential needs of the world’s poorest people, to which they should be given overriding priority, and the idea of limitations which is imposed by the state of technology and social organization on the environment’s ability to meet both present and future needs”.

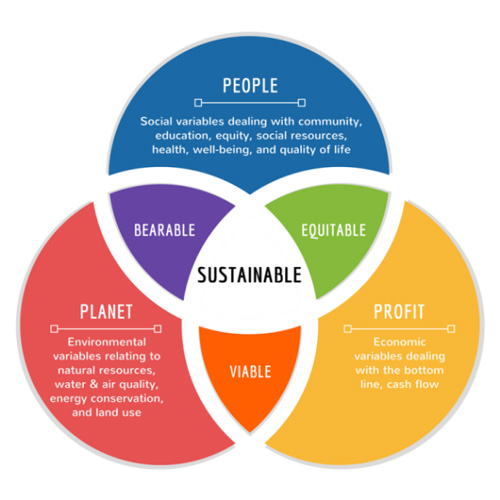

When we talk about the notion of sustainable development, we commonly talk about 3 interdependent cornerstones:

- The environmental cornerstone: this cornerstone consists in the preservation, improvement and valuation of the environment and all natural resources on a long term. It also involves the protection of biodiversity (fauna and flora) and the fight against global warming by reducing carbon emissions.

- The social cornerstone: it consists in meeting all human needs, while answering to an objective of ethics, social equity and reduction of inequalities. This cornerstone also concerns the fight against exclusion and all forms of discrimination.

- The economical cornerstone: this cornerstone is based on the development of growth and economic efficiency through sustainable production and consumption patterns. As an example, the definition of a price will be influenced by the different elements and stakeholders which enter into the manufacturing process.

Today, we hear more and more talks about a new element that could be considered as the 4th cornerstone of the sustainable development: culture. According to the UNESCO, cultural heritages as well as the cultural and creative industries are both catalyst and vehicle for economic, environmental and social dimensions of sustainable development.

source: maricopa.edu

Circular economy: what is this?

According to the French Ministry of Ecological and Solidarity Transition, the circular economy “refers to an economic concept that is part of sustainable development and whose objective is to produce goods and services while limiting the consumption and waste of raw materials, water and energy sources. It is a question of developing a new economy, circular, and no longer linear, based on the principle of “closing the life cycle” of products, services, wastes, materials, water and energy”.

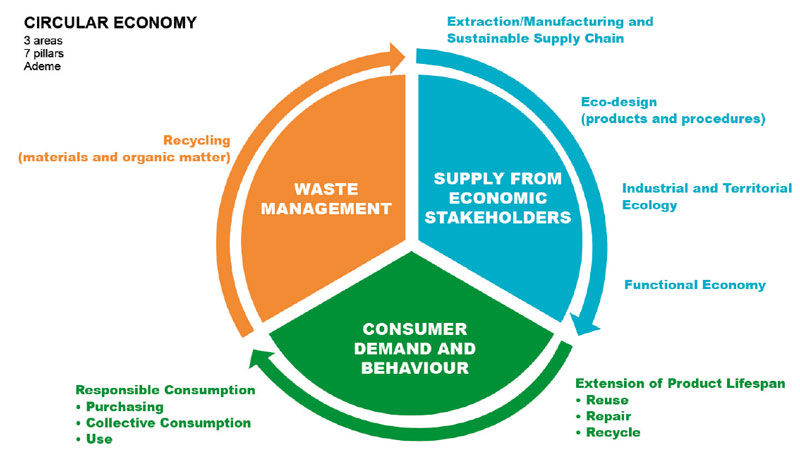

To represent the major issues of the circular economy in our consumption society in a more concrete way, the ADEME, the French Environment and Energy Management Agency (in French, l’Agence de l’Environnement et de la Maîtrise de l’Énergie) has defined, as for the sustainable development, 3 main pillars in which are spread 7 main categories :

- Supply from economic stakeholders:

- Sustainable supply chain (extraction and manufacturing) targets a reliable extraction and manufacture of the resources while limiting operating scraps and environmental impacts.

- Eco-design is based on taking into account the entire cycle of life of a product or service from its design step in order to limit the impacts on environment.

- Industrial and territorial ecology represents a business-to-business organization mode using flow exchanges and needs sharing.

- Functional Economy favored use to possession and tends to sell services related to products rather than the products themselves.

- Consumer demand and behavior:

- Responsible Consumption tends to drive the consumers to take their decision by taking into account all the environmental impacts that occur in all the different steps of the life cycle of a product.

- Extension of Product lifespan in particular by using repaired, resale, second-hand donation or second-hand purchase in a context of reuse.

- Waste management:

Recycling which is simply the fact of reusing the raw materials from wastes.

Circular ecnonomy

source: ADEME

EURAGGLO and the agglomeration field: a market and an activity directly concerned by the notions of sustainable development and circular economy:

Euragglo has been designing, manufacturing and installing briquetting and compaction units all over the world since 1992. Agglomeration, which is the historical activity of our company, is a process consisting in particle size enlargement and densification carried out on finely divided solids with the use of pressure.

This process allows the recovery of by-products (fines, “wastes”…) by agglomerating them into a larger-size solid which can be reused in the production line as a secondary raw material, in order to create a “virtuous circle”. By this way, if we use the definition of sustainable development we just gave, industrial actors play on two levels: the economical one where all the secondary raw materials are totally used and reused but also on the environmental level where residues that were not recovered are substituted to primary resources.

Also, if we look at the pattern of circular economy gave by ADEME, we can see that Euragglo and agglomeration in general, are involved in several of the main pillars of this model:

- Recycling: this is one of the main principles on which the agglomeration market is based. Indeed, as we said, this activity consists in giving a second life to by-products, by recycling them under a secondary raw material briquette form.

As an example, we offer briquetting solutions for steel-mill by-products, by recovering these by-products, a priori unusable as they stand, in order to recycle them in the melting processes.

Various types of steel-mill by-products can be briquetted by Euragglo briquetting presses : mill scales, steel grits, blast furnace sludges, furnace dusts (BOF, EAF, AOD) as well as various fines such as DRI, ferro-alloys (FeMn, FeCr, SiMn, FeSi…), coal, iron oxides, coke…

And according to customer needs, steel-mill by-products can be briquetted in different sizes and shapes (pillow-square or ovoid) but the raw material should always respect some necessary characteristics to allow their briquetting (a limited moisture content – generally between 2 and 3 % – an acceptable size range…).

Before entering the rolls of the briquetting press, raw material is mixed with a binder in order to obtain mechanically solid agglomerates. After the briquetting step, briquettes are screened, a step that separates good quality briquettes that will then be stored for curing (forced or natural) and fines and flashings which will returned to the secondary raw material silo in order to be recycled into the agglomeration line. Briquettes produced are ready to be used as secondary raw materials.

Another example is the one of mineral fertilizer production and more precisely granule production which is particularly concerned by secondary raw material or production by-products recycling principles.

In order to produce fertilizer granules, we use a compaction-granulation process which means that the raw material should first be compacted into a flake form (generally between 10 to 20 mm thick) before being crushed and screened to obtain the perfect size granules (e.g. 2-4, 2-5 mm).

As an example, by-products, biological or not, from amino acid production, dried or carbonized organic fertilizers (manures) can replace mineral raw materials (P and K) or produced from gas or petroleum (N).

- Responsible consumption: industrial companies that have chosen to turn to this type of technology do reflect a motivation to reduce their ecological impact, which obviously results from a real awareness of the potential harmful consequences of their activity on the environment but also from the possible loss of money represented by unused streams of by-products.

- Extension of product lifespan: of course, equipment sold by Euragglo are not single use machines. They are repairable and usable on long operating periods since they’re based on solid and technologically advanced design and construction criteria.

- Functional economy: Indeed, Euragglo activity is partly concerned by this topic since our company offers to prospective and present customers a toll production service, either to companies with small production needs who do not require the final purchase of an equipment or to companies that first want to check briquettes quality and characteristics compared to a process or a market before embarking on this activity and finally into an investment.

In addition to this toll production service, Euragglo also offers an equipment rental service, avoiding once again the purchase of an equipment when is not necessary, whether from a capacity or a production need point of view. This does reduce considerably the risk level for our customers.

If you too want to change your production habits in order to limit your environmental impact and save money, do not hesitate to contact us by email at euragglo@euragglo.com or by phone at 03.27.09.00.09.

We will be glad to inform you about the different agglomeration technologies we offer and help you to define the best solution for your activity.