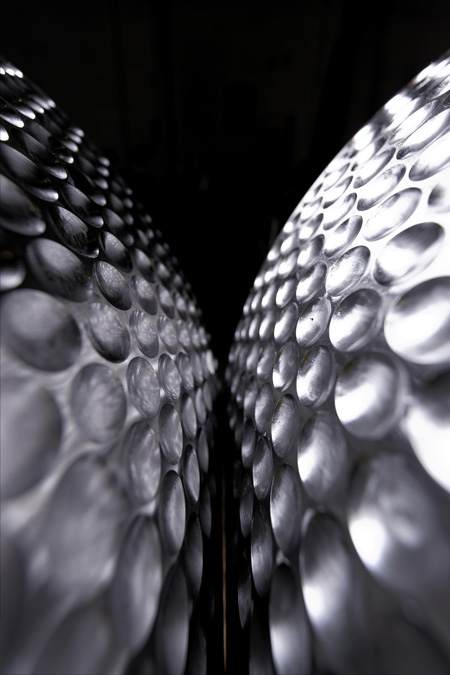

Briquetting and Granulation

equipment

equipment

- Imagine

- -

- Design

- -

- Manufacture

- -

- Install

- -

- Maintain

Our activities

What we do

EURAGGLO is part of the KÖPPERN Group, world leading industrial Group, offering equipment and services to the process industry in the area of agglomeration of finely divided powders and in the area of interparticle crushing.

Specialized in briquetting, compaction and granulation equipment, we help our customers improve their efficiency and their profitability through tailor-made solutions adapted to their field of industry.

Equipment & services

News

Euragglo and sustainable development

Euragglo and sustainable development

Euragglo allows you to save money by recovering through agglomeration your by-products and production fines.